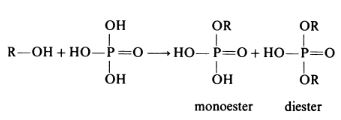

This equation is an over simplification as a mixture of mono-, di- and triesters plus polymeric esters are formed together with some of the original phosphoric acid. There are two phosphorylating agents in use, tetraphosphoric acid (TPA) and phosphorous pentoxide (P2O5) The reactions involving TPA are now well understood, and the major product is the monoester. The reactions involving P2O5 are more complex but the major product is diester. The majority of commercial products are made with P2O5 and are therefore predominantly diesters, but with significant amounts of monoester and polymeric esters present.

General properties

General

The phosphate esters have properties intermediate between the ethoxylated non-ionics and the sulfated derivatives. Thus they have good compatibility with inorganic builders. good emulsifying properties and a foaming capacity intermediate between the low-foaming non-ionics and the high-foaming ether sulphates.

Solubility

Free acids have good solubility in both water and organic solvents with the acidity comparable to phosphoric acid. However, depending upon the hydrophobe, some phosphated non-ionic surfactants are insoluble in water whilst the alkali metal salts are soluble. Sodium salts of mono esters with long alkyl chains have poor solubility in water. Alkali metal salts of products made from ethoxylated surfactants by reaction with P2O5 (high diester content) are usually quite soluble. However many commercial products are potassium salts which have better solubility than sodium salts.

Chemical stability

Resistant to hydrolysis by hot alkali and color not affected, stable to acid solution and high temperatures.

Compatibility with aqueous ions

TPA phosphate ion gives products with better electrolytic compatibility than with P2O5; can sequester iron and other metal ions; polyoxyethylation gives good resistance to hard water and concentrated electrolyte.

Surface active properties

The surface tension of the diesters decreases with increasing alkyl chain length; branching of the alkyl chain gives lower values than straight-chain alkyl groups.

Functional properties

Efficient oil emulsification (better with P2O5 products); good detergency on fibres; diesters have good wetting properties with low molecular weight giving the best wetting properties; excellent rinsability; lower foam than the corresponding sulphate or sulphonate; corrosion inhibition; antistatic properties; good dispersing agents (better with P2O5 products); hydrotrope properties (particularly with short alkyl chains).

Disadvantages

Only moderate reduction in surface tension of aqueous solution; more expensive than sulphonates; sodium salts not always water-soluble so the more expensive potassium and alkanolamine salts are needed for aqueous solubility of a neutral phosphate ester; the compositions of most phosphate esters are complex and difficult to analyze.

Applications

Textiles

Lubricant and/or emulsifier with anticorrosive properties; wetting agent in the presence of alkali, e.g. kier boiling (nonylphenol + 13EO + P2O5); “dye bath additive for even dying and better penetration; short-chain alkyl esters are efficient antistatic agents in spin finishes for synthetic fibers (C8 alcohol + P2O5).

Detergents

Solubilization of non-ionics in high concentrations of electrolyte; dry-cleaning soaps for antistatic effect.

Agriculture

Emulsifying agents in herbicides especially when blended with concentrated liquid fertilizers; dispersing agents for aqueous dispersions of insoluble herbicides or insecticides to give better storage stability of the concentrated dispersion plus better flow properties; lubricant additive and metalworking; Cl2 alcohol + 6EO + P20S gives good emulsifier for mineral oil but also good load carrying properties.

Antifoams

Cl8 alkyl monoester products are good antifoams for anionic surfactants.

Specification

Difficult but essential as the product being used is a mixture. A test of

surfactant properties is often the best method of quality control. However

most of the chemical tests are adequate for showing batch to batch variation.

% Active, 100% for acids, 30-45% for potassium salts.

mg KOH/g to pH 5.2,85-110, an indication of high monoester concentration.

mg KOH/g to pH 9.3,160-220, an indication of high diester concentration.

Titration with KOH to two particular pH points is more useful than a

normal acid number.