Shampoos may be made in various physical forms, liquids, creams or pastes, aerosol and dry. The majority are liquids, either clear or pearlized. The principal ingredients of most liquid shampoos can be classified as:

- Diluents (usually water)

- Primary surfactants

- Secondary surfactants

- Foam stabilizers and boosters

- Conditioning agents

- Thickeners

- Pearlizers/opacifiers

- Other additives (functional or otherwise)

- Colors

- Perfumes

- Preservatives

Many ingredients are multifunctional and therefore do not clearly fall into one category.

Surfactants

There is no clear distinction between a primary and a secondary surfactant. Primary shampoo surfactants are usually anionic and inexpensive, with sodium laureth sulfate being easily the most widely used. A whole mass of different surfactants are available including:

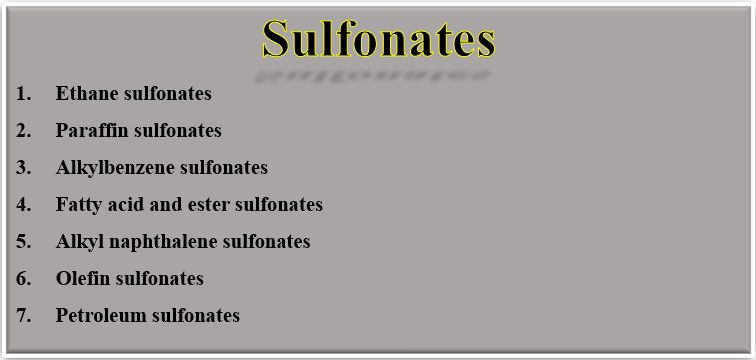

Alkyl sulfates, Alkyl ether sulfates, α-Olefin sulfonates, Paraffin sulfonates, Isethionates, Sarcosinates, Acyl lactylates, Sulfosuccinates, Carboxylates, Protein condensates, Betaines, Glycinates, Amine oxides, Alkyl polyglycozides.

Within these groups, there are many variants, depending on chain length, chain-length distribution, degree of ethoxylation, chain branching and numerous other variables.

The surfactants used in a shampoo need to be selected on the basis of a whole range of properties, including:

- Cost

- Foam height

- Foam texture

- Detergency

- Irritancy

- Ease of handling and mixing

- Compatibility with other ingredients

- Color

- Odor

- Purity

- Biodegradability

Thickeners and foam stabilizers

There are several methods by which shampoos may be thickened:

- alkanolamides or their alternatives

- polymeric materials

- electrolytes

Many of these ingredients are multifunctional, and most products use more than one.

alkanolamides or their alternatives

By far the most commonly used alkanolamide is coconut diethanolamide; Both monoethanolamides and diethanolamides are widely used.

Monoethanolamides are more effective, both as foam stabilizers and as thickeners, but have the disadvantage of being waxy solids requiring a hot process to incorporate them into the mix.

Diethanolamides are very dependent on the method of manufacture and can vary considerably in composition from supplier to supplier.

While lauric, lauric/myristic and coconut mono- and diethanolamides dominate, other alkanolamides find more limited use, e.g. oleic and linoleic diethanolamide in gel shampoos based on SLES (where their thickening effect is remarkable), lauric monoisopropanolamide (probably the most effective thickener and foam stabiliser of the group), stearamides (as part of a pearlescing system) and ricinoleic diethanolamide, said to possess some conditioning properties.

Some surfactant systems are notoriously difficult to thicken, not responding well to electrolyte additions. Various raw materials manufacturers have developed alternatives to alkanolamides which overcome this difficulty. These include PEG-6000 distearate, PEG-55 propylene glycol oleate and PEG-120 methyl glucose dioleate.

polymeric materials

Polymeric materials used for thickening shampoos include a variety of natural gums, such as guar, locust bean, carrageenan, and tragacanth.

In practice these materials, in unmodified form, find little use in today’s shampoos, and this class of thickeners is dominated by cellulosic derivatives, such as hydroxyethyl cellulose, carboxymethyl cellulose, and hydroxypropyl methylcellulose. These materials are usually dispersed in all or part of the water in the formulation before adding the other ingredients. Non-ionic cellulose derivatives, such as hydroxyethyl cellulose, exhibit an inverse cloud point and this can be used to good effect by adding the gum to water heated to a temperature above the cloud point. The gum, insoluble at this temperature, will disperse to form a milky liquid which, on cooling, will give a clear and lump-free solution. Some gums are available in a surface-treated form.

Electrolytes

The effect of electrolytes on the viscosity of surfactant systems is a result of the increase in ionic density of the solution with its consequent effect on micelle size and shape.

Addition of electrolyte beyond a certain point will cause thinning, often quite rapid, and an increase in cloud point. The point at which the maximum in the viscosity/electrolyte curve occurs will depend on many factors, including concentration, presence of alkanolamides, level of free fatty alcohol or ether in the surfactants, and the effect of the perfume.

Conditioning agents

The majority of active conditioning agents are cationic surfactants and are therefore incompatible with the anionic surfactants that are the basis of nearly all shampoos. To take an extreme example, the addition of cetyl trimethyl ammonium chloride to a shampoo based on sodium lauryl sulfate will result in the formation of cetyl trimethyl ammonium lauryl sulfate, a very large and fairly useless molecule which will do its very best to precipitate out of solution. The properties of both the anionic and cationic molecules present can be modified to make them more compatible; the base itself can also be made more amenable to the inclusion of both of these seemingly antagonistic species.

- The base can be made less anionic in character by including a reasonably high percentage of amphoteric surfactant.

- The charge density on the cationic and anionic can be reduced.

- The use of a polymeric cationic material, with the overall effect one of reduction of charge density.

- The level of active matter can be made high enough for any anionic/ cationic complex to be solubilized by the large excess of anionic present.

- A sufficiently high level of non-ionic will assist compatibility.

Other means of conditioning, not based on cationic materials, are available.

The substantivity of cationics is an electrostatic effect restricted to the outside of the hair shaft where the charge lies. Where there is significant damage to the hair shaft, however, the story is different. Partially hydrolysed proteins can be shown to be effective in ‘repairing’ split ends. Both panthenol and amino acids have been shown to penetrate the undamaged hair shaft and, once there, to impart worthwhile conditioning effects. Panthenol is well-documented and, properly formulated into a product, can justify claims for moisturizing and hair thickening, as well as conditioning. Sufficient active ingredient must be used to justify any claims made.

A variety of other materials have been used as conditioning agents in shampoos, including various vegetable oils, vitamins, lanolin and its derivatives, herbal extracts and some speciality silicones. The speciality silicones merit examination since they are currently popular, offer an alternative to cationic materials and should be less prone to ‘build-up’ or ‘over-conditioning’. Silicone glycol copolymers can assist gloss and conditioning and seem to be substantive, to a degree, from shampoo bases, although they do reduce viscosity. More recently, very high viscosity dimethiconol dissolved in cyclomethicone has become more popular, although ‘build-up’ problems with shampoos using this ingredient have been reported. An even more recent system advocates the use of several silicones together, at quite low levels, to give an optimized conditioning effect.

Opacifiers and pearlizers

Opacification of shampoos is usually used for aesthetic reasons, although it is occasionally a useful technique to use when the product cannot be made completely clear. If a pastel color is required, then opacification is a prerequisite.

Opacification may be achieved simply by adding a small amount of fine, intensely white polymer dispersion. For ease of dispersion and subsequent product stability, dilution of the opacifier to a 10% solution with water before addition to the main mix is usually recommended.

The main factors that affect the appearance of the ‘pearl’ are:

(i) Composition of the stearate ester

(ii) Presence of alkanolamides and other materials

(iii) Rate of cooling

(iv) Shear rate of stirring

(v) Composition of the base

Colors and color fading

A large number of colors are available, but the list is restricted by the regulations governing their use wherever the product is sold. Whilst higher purity colors are more expensive than technical grades, it is preferable to use colors which meet both the EC and US specifications whenever possible; such colors will be acceptable virtually anywhere in the world. The cost premium is minimal.

Some aspects of color stability, e.g. stability to pH variation and light, can be predicted but, unfortunately, the number of possible interactions involving the color in a base as complex as a modern shampoo means that color stability (especially to light) must be individually evaluated for each formulation.

Color fading can usually be minimized by incorporation of a suitable UV absorber. Water-soluble absorbers usually work best in shampoos, the most popular being benzophenone-4 and benzophenone-2. However, it is always worth trying others, both UV-A and UV-B absorbers. Usage levels are low, generally 0.05-0.1%.

Colors should be added in solution and not as solid material. Aqueous solutions of colors require preservation -an aqueous/alcoholic base is safer.

Other additives

Sequestrants, such as EDTA (ethylene diamine tetra-acetic acid) salts, are sometimes added at low levels to aid rinsing in hard water and boost the efficacy of preservatives. The majority of other shampoo additives are not truly active ingredients, being included for marketing reasons rather than performance.

Anti-dandruff shampoos have been a growth area in recent years, with various active ingredients having been used. The widespread adoption of zinc pyridinethione as an active ingredient has substantially increased the use of anti-dandruff shampoos. This ingredient is usually supplied as a 48% dispersion and is a very dense solid which needs to be suspended in the product. To obtain stability this requires a suitable clay- or gum-type suspending agent, with fairly high yield-point, and restricts the formulator to producing an opaque product. A more recently available anti-dandruff agent is piroctone olamine, which is water-soluble and therefore much easier to use.

Baby shampoos form another important category. Babies’ hair does not require a high level of detergency to clean it and, above all, the products must be non-irritant to eyes and skin, or as close to this ideal as possible.

The final class of shampoos that will be mentioned here anti-build-up

shampoos is perhaps the simplest. As the name suggests, these shampoos are formulated to help remove excess build-up of conditioning agents and styling aids. Consequently, they are usually quite simple systems, with good detergency and containing no conditioners. Since most conditioners (whether from shampoos, conditioners or styling aids) are applied to the hair under acidic conditions, anti-build-up shampoos are left alkaline. (This can also help remove acid resins.) For the same reason, ‘lacquer-removing’ shampoos, the ancestors of this class of product, usually contained an excess of mild alkali (e.g. TEA).

Perfumes

Perfumery is a complex subject in its own right, but most of the detailed knowledge is required in creating the fragrances; the more mundane process of using these fragrance creations in the product formulation requires less ability, although selection may not be so easy.

Occasionally, one is required to develop a shampoo as a line extension to a fragrance-led range. Where the range already contains toiletry products it may only be necessary to include an existing perfume at the appropriate level. If the range consists entirely of alcoholic-based perfumery products, it may be necessary for the fragrance house concerned to modify the perfume compound to achieve acceptable performance in a detergent base. At the other extreme, in very cheap shampoos, the perfume is sometimes regarded as quite incidental. There have been attempts to market shampoos with high levels of fragrance (although not part of a fragrance-led range), even fragrances designed to persist on the hair after washing, but these have met with limited success.

Fragrance can often be simply added to the shampoo after the completion of any hot part of the process. If solubility is a problem, then the perfume can be premixed with a suitable solubilizer before addition, the ratio within the premix being determined by trial and error.

Preservatives

The main concerns, as with all products destined for use on the human body, are resistance to spoilage and protection of the consumer. In the case of shampoos, it is particularly important to ensure that the product contains no pathogenic organisms, especially those capable of damaging the eyes. A variety of preservatives are available to the formulator and all of those in the following list have been commercially used in shampoos, either alone or in various combinations.

Parabens (the shorter chain esters are the most soluble)

Imidazolidinyl ureas

2-Bromo-2-nitropropane-l,3 -di 01

5-Bromo-5-nitro-l,3-dioxane

Dimethyl dimethylol (DMDM)/hydantoin

Methylchloroisothiazolinone and methylisothiazolinone

Phenoxyethanol

Diazolidinyl urea

Methyldibromoglutaronitrile

Quaternium-15

Sodium iodate

Glutaraldehyde

Many of the surfactants used as raw materials for shampoo manufacture are already preserved, and the contribution of this portion of the preservative system must be taken into account. Provided that sufficient quantity is being ordered, most manufacturers of surfactants are happy to consider alternative preservative systems. Other ingredients, such as proteins and herbal extracts, may also be preserved and it is therefore quite conceivable that a newly developed shampoo may already contain a number of different preservatives.

Apart from the various performance-based choices inherent in selecting a preservative system, which are well documented elsewhere, there is also the problem of legislation; it is vital to know in which countries the product is to be sold in order to ensure that the product meets local requirements.

This is true of all raw materials, but preservatives, particularly formaldehyde, (along with colors and ultraviolet absorbers) are a special case and are often heavily regulated. The chosen preservative system should pass a recognized (e.g. BP, USP) challenge test in the final formulation, preferably when freshly prepared, and when aged. If such testing can be accompanied by meaningful preservative assays, so much the better.

Before leaving shampoos, the question of impurities should be considered. Most surfactants contain small amounts of numerous by-products. Of particular concern are the nitrosamines and l,4-dioxane.

Nitrosamines are potent carcinogens derived from the reaction of nitrite and secondary amines. The most important in cosmetics and toiletries is nitroso diethanolamine (NDELA), which is formed, under some circumstances, from diethanolamine. To avoid this, lower grades of triethanolamine (which can contain substantial amounts of diethanolamine) should be replaced with a higher grade (99% + purity). As mentioned earlier, some coconut diethanolamides can contain quite large amounts of diethanolamine and it is advisable to replace these with other alkanolamides or alternative thickeners/foam boosters.

l,4-Dioxane is a cyclic dimer of ethylene oxide and can arise whenever ethoxylation is used in the manufacture of a surfactant. Like NDELA, it has been identified as a carcinogen and some European countries are now tending to use non-ethoxylated surfactants to minimize dioxane levels. Control can be exercised at each stage of surfactant manufacture and it is now possible to buy 27% active SLES with dioxane < 25 ppm.

References:

1- Hunting, A.L.L. The Encyclopaedia oj Shampoo Ingredients. London Micelle Press.

2- Rieger, M. (1988) Surfactants in Shampoos. Cosmet. Toilet. 103(3)

3- Milwidsky, B. (1989) Soapless shampoo actives. Household and Personal Products Industry 26(9) 58; 26(10) 52; 26(11) 55.

4- Lomax, E. (1989) An introduction to surfactants. CTMS XIV 15; XV 21; XVI 15; XVII 31.

5- Harry, R.J. (1982) Harry’s Cosmeticology. 7thedn. Chapter 24, p. 433. Longmans, London.

6- Donaldson, B.R. and Messenger, E.T. (1979) Performance characteristics and solution properties of surfactants in shampoos. Int. J. Cosmet. Sci. 1 71.

7- Alexander, P. (1986) The Miranol amphoteric surfactants, carboxylates and sulphonates, their chemistry and application. Soap. PerJumery Cosmet. 59(9) 493.

8- Lomax, E. (1988) Newpolyfunctional amphoterics. CTMS 1(4) 18.

9- Mizayawa, K. and Tamura, U-hei. (1993) N-Acyl-N-methyllaurates. Cosmet. Toilet. 108(3) 81.

10- Salka, B. (1993) Alkyl polyglycosides, properties and applications. Cosmet. Toilet. 108(3) 89.

11- Kamegai, J. and Onitsuka, S. (1993) Alkylsaccharides, use in shampoo. Manufacturing Chemist 64(9) 20.

12- Domingo Campos, F.J. and Druguet Tantina, R.M. (1983) Evaluation of the foaming capacity in shampoos; efficacy of various experimental methods. Cosmet. Toilet. 98(9) 121.

13- Larson, R.I, and Bishop, W,E, (1988) New approaches for assessing surfactant biodegradation in the environment. Household and Personal Products Industry 25(5) 84.

14- Carson, H.C. (1990) Surfactants-environmental issues. Household and Personal Products Industry 27(6) 41.

15- Gilbert, P.A. and Pettigrew, R. (1984) Surfactants and the environment. Int. J. Cosmet. Sci. 6(4) 149.

16- Grandval, G. (1986) Evaluating and choosing fragrances for functional products. Cosmet. Toilet.lOl( 6) 69.

17- Harding, N. (1986) Evaluation of perfume submission from expert to consumer-A review of approaches. Cosmet. Toilet 101(6)73.

18- Aarts, P. (1986) Evaluation of fragrances from both captive and external sources. Cosmet. Toilet. 101(6) 79.

19- Beeding, J. (1993) Formulating and fragrancing multi-functional shampoos. Manufacturing Chemist 64(11) 18.

20- Blakeway, J.M. and Fabrizi, G. (1983) Substantivity of perfume materials to hair. Int. J. Cosmet. Sci. 5(1) 15.

21- Orth, D.S. (1989) Microbiological considerations in cosmetic formula development and evaluation. Cosmet. Toilet. 104(4) 49.

22- D.F. Williams, W.H. Schmitt (1996), Chemistry and Technology of the Cosmetics and Toiletries Industry

23- Cosmetics preservatives encyclopaedia-antimicrobials (1990) Cosmet. Toilet. 105 49.

24- Busch, P., Hase, c., Schutze, R., Hensen, H. and Lorenz, P. (1987) Hair conditioning effect of guar hydroxypropyl trimethylammonium chloride. Cosmet. Toilet. 102(5) 49.

25- Needs, S.G. (1984) Methods oflight fastness testing. Presenting at the SCS Symposium on Product Stability, Coventry, November 1984.

26- Hair Sunscreen Study VD-OJ-85. VanDyk&Co.

27- Sendelbach, G., Liefke, M., Schwan, A. and Lang, G. (1993) A new method for testingremovability of polymers in hair sprays and setting lotions. Int. J. Cosmet. Sci. 15(4) 175.