Cleaning is a complex task, depending not only on the formula composition but on the nature of the substrate, the soil, and the way cleaning is conducted: product concentration, water hardness, and temperature are among the important variables here. The formulator can determine the composition of the product and make recommendations on how to use it, but he or she does not control the other parameters. To formulate effective products, it is a good idea to develop a system whose performance is as independent as possible of uncontrolled factors.

In hard water areas, fabric encrustation can be controlled by alkaline earth sequestering agents such as sodium tripolyphosphate, citrate or zeolite, to which can be added a scale inhibitor, usually sodium polyacrylate.

Soil removal results from complex interactions between the soil, the substrate, and the cleaning solution. Thus, cleaning compositions must be adopted not only to the type of the soil but also to the substrate. Substrates found in the household can be hard (e.g., glass, ceramic, metal, plastic) or fabric (e.g., cotton, polyester, polyamide) surfaces.

In this article, we will know more about the soil types and the mechanism to remove these soils.

Water-Soluble Soils

Many soils are soluble in water. Typical examples are salts, such as sodium chloride left after the evaporation of cooking water, and sugar-resulting, for instance, from the spillage of a soft drink. Such soils are best removed with clean, cold water and are seldom of great concern for the housekeeper. They may be an issue, however, when they occur on items that must be dry-cleaned. This is because dry cleaning is based on organic solvent extraction, and water-soluble materials usually are not soluble in the organic solvents used in this process.

Water-soluble soils are best removed with clean water by a simple solubilization mechanism. We will not elaborate on this type of soil.

Oily Soils

By oily soils we mean soils mainly composed of nonpolar hydrocarbons such as diesel and motor oils. These materials are usually liquid and highly hydrophobic, which means that they do not mix with water. These oils are very soluble in many organic solvents and particularly in halogenated hydrocarbons. They are quite easily removed by dry cleaning. Dry cleaning is not always possible, however, if the oil is spilled on a floor or the wallpaper, it is not advisable to use solvents. An important nonpolar soil is squalene, a high molecular weight, unsaturated hydrocarbon present in the skin. Since the function of squalene is to protect the skin, ideally it should not be removed from the skin. Skin irritation (erythema) can result if this precaution is neglected.

Greasy Soils

Greasy soils mainly refer to triglycerides and their derivatives: mono- and diglycerides, fatty acids, and so on. These materials are either animal or vegetable in origin. They are more polar than the oily materials but not polar enough to be dissolved by water.

Greasy soil must be regarded as a suspension of small crystalline particles in an amorphous, high viscosity matrix. The melting temperature increases if the crystalline particles are bigger. The temperature required to melt the grease obviously increases with the proportion of crystalline material. In general, the higher the crystallinity of a grease, the more difficult is its removal.

Most unsaturated triglycerides (e.g., peanut, soya, or corn oil) are liquids and accordingly should be easier to remove. This is unfortunately not the case, however, because the presence of the unsaturation is responsible for chemical reactions induced mainly by temperature. When unsaturated greases are heated (cooking), the double bonds can be oxidized and polymerization takes place, leading to an insoluble mass.

Mechanism of Oily-Greasy Soils Removal

Oily and greasy soils are not water-soluble and cannot be satisfactorily removed with pure water. As a consequence, there is tension at the interface between the soil and water. This tension, which corresponds to the energy needed to bring the oil in contact with the substrate, arises because the cohesive energy of the oil is not the same as that of the substrate. Water is not able to wet the surface of the soil.

Surfactants need to be added to water to reduce the interfacial tension to a reasonable value, allowing water to wet the soil, which actually means the displacement of air by the aqueous medium. This stage is essential because it must be completed before any detergency can take place. Depending on the nature of the soil, the surfactant used, the temperature, and the mechanical action, different things can happen.

Roll-Up

If the soil is liquid, either an oil or a grease above its melting temperature, the so called roll-up mechanism can take place [4]. When a liquid oily soil lies on the surface of a solid substrate, there is an interfacial tension at the soil-substrate interface. The oil droplet forms with the substrate an angle, which results from the balance between the surface forces. The surface tension between the substrate and the gas phase (air in the present case) tends to spread the oil on the surface (to reduce the surface of contact). The interfacial tension between the oil and the substrate tends to reduce the oil-substrate contact and to re-form the drop. The surface tension between the oil and the gas phase is not in the plane of the substrate. Its projection on the plane nevertheless must be taken into account to balance the forces.

The interfacial tension between the oil and the substrate is usually lower than the surface tension between the substrate and the gas phase, especially on organic surfaces such as fabrics and polymeric hard surfaces. The result is that the contact angle is usually small, which is synonymous with good wetting, and sometimes zero, which is synonymous with perfect wetting.

When the substrate and the oil are submerged, the surface tension between the substrate and the gas phase is replaced by the interfacial tension between the substrate and water, and the surface tension between oil and gas is replaced by the interfacial tension between the oil and water. The result is usually another contact angle.

If an appropriate surfactant is dissolved in water, the effect is a strong reduction of the substrate-water and oil-water interfacial tensions, due to the adsorption of surfactant molecules at the water-oil and water-substrate interfaces. Of course, the oil-substrate interfacial tension is not affected, since water does not diffuse to that interface. The system evolves towards new equilibrium state, characterized by a higher contact angle. Mechanical action causes droplets of oil to be removed from the substrate, and only a small quantity of oil is left.

It is evident that the higher the equilibrium contact angle, the more easily the soil is removed. If the reduction of the interfacial tension is so strong that the sum of the oil-water and substrate-water interfacial tensions reaches the oil-substrate interfacial tension, the contact angle is 180°, which means that no oil is left on the substrate (spontaneous perfect cleaning).

It must be pointed out that the cleaning operation depends significantly on the kinetics of the operation. The surfactant needs to diffuse rapidly to the surfaces to reduce the interfacial forces. Hydrodynamics also plays a key role, in as much as roll-up implies the motions of fluids. Cleaning based on roll-up is more difficult on irregular substrates such as fabrics, capillary forces are almost unpredictable in real cases, and the result is often incomplete soil removal.

- Emulsification

Emulsification is probably one of the most important mechanisms contributing to oily greasy soil removal. An emulsion is a dispersion of a liquid in another liquid in which it is not soluble. Mechanical agitation is able to generate an emulsion, but, to remain dispersed, the oil droplets need to be coated with a layer of surfactant molecules to reduce the interfacial tension with the continuous phase. Since the surface area increases when the droplet size decreases, efficient surfactant systems are required to achieve small particle sizes. Since a surfactant contains a part that is completely water-soluble (its polar head group), the interfacial tension could go to very low values and even completely vanish. Unfortunately, such an extreme situation never occurs, owing to surfactant shape and micellization.

There is a thermodynamic equilibrium between the surfactant concentration in water and the surfactant adsorbed on any surface, and particularly the surface of the oil droplets. Increasing the surfactant concentration in water also increases its adsorption.

Of course, a high surfactant concentration may at first appear to be beneficial, since micelles act as surfactant reservoirs. This is only partly true, however. At surfactant concentrations above 5-10 times the CMC, the micelles can induce flocculation of the oil droplets, which has an adverse effect on the physical stability of the emulsion. The physical stability of the emulsion is an important factor in detergency, but it is not the only one. If the interfacial tension is too high, it may no longer be able to balance the oil-substrate interfacial tension. As a result, the equilibrium contact angle of the oil on the substrate is no longer 180° and the residual oil is left on the substrate.

- Solubilization of Oil

Solubilization occurs to a significant extent only in some cases and always above the CMC of the surfactant system. “Solubilization” is not really the appropriate term, in as much as oil is not molecularly dissolved in the water phase but is absorbed inside the core of the surfactant micelles.

The solubilization, or oil uptake capacity of a surfactant system depends on the shape of the micelles. Globular micelles, like those obtained with such highly water-soluble surfactants as anionics (sodium lauryl sulfate, sodium alkyl benzene sulfonate, etc.) exhibit a low oil uptake capacity. Accordingly, solubilization does not contribute significantly to detergency by cleaners based on anionic surfactants.

Nonionic surfactants such as polyethoxylated fatty alcohols exhibit a much higher potential for solubilization. The oil uptake capacity of globular micelles is limited because the addition of oil necessarily results in an increase of the micelle surface exposed to water. Even if the interfacial tension is low, an increase of surface implies an increase of energy that can hardly be balanced by the entropy of dispersion of the oil in the micelles. Moreover, the interfacial tension between a flat oil surface and the aqueous surfactant solution creates a kinetic barrier to spontaneous solubilization, as the adsorption effectiveness is not maximum. The adsorption effectiveness, which is maximum when the interfacial tension is minimum, can be related to the shape of the surfactant micelles.

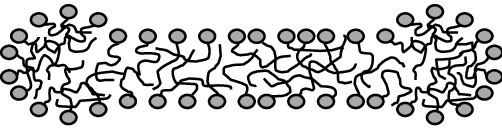

Rodlike micelles are much better adapted to higher oil uptake. A surfactant forming rodlike micelles induces a lower oil-water interfacial tension and accordingly facilitates the transfer of oil from the substrate to the core of the micelles. The absorption of oil allows micellar internal tensions to relax, and the volume increases to a significant extent without increasing the surface exposed to the water phase. Rodlike micelles are obtained if the hydrodynamic volume of the hydrophilic group is slightly higher than that of the hydrophobic group. The packing induces a moderate curvature. If the natural radius of curvature of the surfactant molecules exceeds their extended hydrophobic chain length, the resulting hypothetical globular micelles will exhibit a hole in the center and, accordingly, will collapse into a rodlike structure. In rodlike micelles, the hydrophilic heads are compressed in the cylindrical part of the micelles, and the hydrophobic tails are compressed in the hemispherical ends. Such a micelle can absorb oil and restore its natural curvature without any surface area increase.

Rodlike micelles can be obtained with ethoxylated nonionic surfactants in a temperature range just below their cloud point. This is the reason for their good reputation as oil solubilizers. Rodlike micelles can also be obtained with some anionic surfactants in the presence of magnesium or calcium counterions.

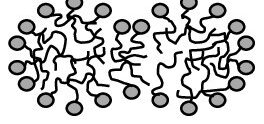

If the hydrodynamic volume of the hydrophilic part is almost equal to that of the hydrophobic part, the oil surface coverage is the most efficient, and disk-like micelles are obtained. Such micelles are not very stable. They usually assemble to form a lamellar liquid crystal, which is a very efficient grease cleaner but cannot necessarily maintain the grease in suspension.

From a general point of view, the solubilization capacity of a given surfactant maximum if it divides equally well between the water and the oily phase. In practice, this happens for a given surfactant system at a temperature referred to as the phase inversion temperature. The phase inversion temperature depends on the surfactant structure, on the oil, and on the presence of ingredients dissolved in water.

- Guy Broze, Colgate-Palmolive, Research & Development Inc., Mechanisms of Soil Remal, Avenue du Pare Indemel B-4041 Milmort (Herstal), Belgium.

- Stevenson, D.G., J. Soc. Cosmet. Chem., XII, 353, (1961).

- Schwartz, A.M., J. Am. Oil Chem. Soc., 48, 566. (1971).

- Wingrave, J.A., Soap/Cosmet. / Chem. Spec., 57, 33 (Nov. 1981).

- Rosen, M.J., Surfactants and Interfacial Phenomena, 2nd ed. Wiley, New York, 1988, p.363.

- Weber, R., Henkel-Referate Int. Ed., 22, 144, (1986).

- Bibetter, J., Roux, D., Pouligny, B., J. Phys. II Fr., 2, 401 (1992).

- Oetter, G., Hoffmann, H., J. Dispersion Sci. Technol., 9(5&6), 459 (1988–1989).

- Kahlweit, M., Strey, R., Angew. Chem. Int. Ed. Engl., 24, 654, (1985).

- Kahlweit, M., Strey, R., J. Phys. Chem., 91, 1553, (1987).

- Kahlweit, M., Strey, R., Busse, G., J. Phys. Chem., 94, 3881, (1990).

- Robert Lange, Detergents and Cleaners, A Handbook for Formulators, 1994.

- Pictures, Ramanathan Nagarajan, Pennsylvania State University | Department of Chemical Engineering.

https://www.researchgate.net/figure/Schematic-representation-of-surfactant-aggregates-in-dilute-aqueous-solutions Structures_fig1_256326325